Share

The Factory Next Door

27. The Doorman's Umbrella

Around 1.5 million umbrellas are reportedly made in the UK every year. We need them. The UK gets around 171 days of rain every year (though that’s across the entire country, thankfully not in one spot!)

On this week’s The Factory Next Door we head to East London to visit one of our last remaining umbrella makers.

Number 27 on our list of the greatest things we make in Britain is The Doorman’s Umbrella by Ince Umbrellas.

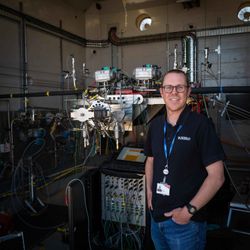

Managing Director Richard Ince chats about the pressures of running a 215-year-old family business, the need to move away from plastic components, and reflects on what he believes are his weaknesses as a boss.

Richard also tells us about making umbrellas for Coldplay, why he entered the business as a 17-year-old, and questions the industry stats as his company doesn’t tell anyone how many umbrellas they make!

Please consider buying me a coffee to keep this show on the road

https://buymeacoffee.com/thefactorynextdoor

(you don’t need to register or create an account!)

Say hello on Instagram @thefactorynextdoor

More episodes

View all episodes

43. The Premium Preserve

31:40|The market for jams and preserves might seem… well, jam-packed, but get your recipe right and you’ll find space to grow.Number 43 on our list of the greatest products we make here is The Premium Preserve.On this week’s The Factory Next Door we visit Bristol to meet Nicola Elliott, founder of award-winning jam maker Single Variety Co.Nicola gives us a tour of her expanding factory as she explains why consistency is so hard in jam-making. She also reveals how a cancelled wedding helped transform her business and shares her big dream for the future.Say hello on Instagram @thefactorynextdoorThe Factory Next Door is supported by AVEVA, a leader in industrial intelligence.Sign up to their bi-weekly newsletter about manufacturing here:www.aveva.com/factory

42. The Mountain Shirt

39:45|There are somethings you can’t know about a company until you’ve bought it and had a riffle through the filing cabinets. In the case of clothing maker Buffalo Systems, it was numerous letters of appreciation from special forces, the military, and mountain rescue teams. Number 42 on our list of the greatest products we make here is The Mountain Shirt by Buffalo.Broadcaster and adventurer Ben Fogle and Savile Row tailor James Sleater acquired the Sheffield-based company earlier this year. On this week’s show, they explain why they had always wanted to buy the company. Plus, we also get an exclusive look at a special new product, consider why Britain has so few global luxury brands, and hear why slow growth is sustainable growth. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

41. The China Mug

32:24|There’s plenty of reasons to buy a British manufacturer right now. On this week’s episode, artist Susan Rose reveals why she’s just done that – acquiring a pottery in Stoke-on-Trent. We take a tour to learn about getting the thickness of mugs just right, the art of the kiln-stack, and why the random-shake of a cup in water is not always what it seems. We also hear about overcoming dyslexia to build a business, and why a little help from your friends is so often invaluable. Plus, Susan gives thanks for the birds, saves a butterfly, and makes a mug for The Factory Next Door. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

40. The Bed Linen

28:16|When the ultra-wealthy want a new set of bespoke bedding for their mansion or superyacht, they email a mill that sits just outside Blackburn, Lancashire. Peter Reed – whose customers include the Royal Household – has been producing handcrafted bedding for more than 160 years. Number 40 on our list of the greatest products we make here is The Bed Linen. Managing Director Sean Clayton explains how the company survived as the British cotton industry rapidly declined, questions why some skills are under-appreciated, and reveals why he never talks politics or religion. We also learn how a single duvet cover can take five hours to complete with 12 embroidery machines, each with nine bobbins on, stitching simultaneously. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

39. The Musical Saw

25:46|The global market for saw blades might be worth $16bn a year, but there’s only one saw factory left in the UK. In today’s show we visit Sheffield’s Thomas Flinn & Co to learn how they’ve been cutting teeth for the past 100 years. Number 39 on our list of the greatest products we make here is The Musical Saw. Director Katie Ellis’ family have owned the company for generations. She explains why heritage crafts must be preserved, how her company has pivoted to survive in the era of cheap imports, and why she’s moving to new premises – just don’t suggest leaving Sheffield. We also learn how to file 200 teeth in under two minutes, get a quick explanation of how musical saws work, and find novel ways to use Lego. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

38. The Rocket Engine

33:45|Earlier this year, Blue Ghost became the first commercial lunar lander to touch down on the moon. Crucial to that mission’s success was its engine – a rocket designed and built in the Buckinghamshire countryside. Number 38 on our list of the greatest items we make in Britain is The Rocket Engine. At a former military base, Dr Ian Coxhill, chief engineer at Nammo UK, shows us around the workshops where propulsion systems are made for space agencies and commercial operators. Ian demonstrates how to recreate the conditions of space at ground level, reflects on the art of engineering, and offers evidence to suggest robots aren’t going to replace humans yet. Plus, we hear the roar of a rocket engine as one is put through its paces at the test facility. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

37. The Oak-Framed Home

33:03|We almost lost the art of building homes from oak in Britain. Thankfully, someone in Herefordshire wasn’t going to let that happen. In today’s show we celebrate a dad who revived the medieval craft and built a business. Number 37 on our list of the greatest items we make here is The Oak-Framed Home. Merry Albright is creative director of Border Oak, and daughter of the founder, John David Greene. She shows us around the firm’s workshops in Leominster as we celebrate the skills her dad had to relearn and then teach others. Also on the show, we consider why we stopped making homes from trees, invite MPs to look through the company’s business accounts, question why the planning system became so combative, and fall in love with a boxed heart. Say hello on Instagram @thefactorynextdoor The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

36. The Resoleable Sneakers

29:22|The American sneaker market is worth $25bn. It is the biggest in the world – and growing. But it’s a crowded market. You need a stellar USP to stand out. Sheffield-based trainer-maker Goral has one – and it’s finding success selling to US sneakerheads. Number 36 on our list of the greatest items we make here is The Resoleable Sneaker. On this week’s episode of The Factory Next Door, Dom Goral shows us how they’ve designed leather trainers with soles that can be replaced. We chat about relocating the factory from Poland to a former school in Yorkshire, how influencers have helped build the brand in America, and why it’s good to question every part of the process. Say hello on Instagram @thefactorynextdoor Please consider voting for the show at this year’s British Podcast Awards: www.britishpodcastawards.com/voting The Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here: www.aveva.com/factory

35. The Dining Chair

32:13|Design a timeless classic and the ripples from that one idea can be felt across industries for decades.Take Ercol’s Windsor Dining Chair, number 35 on our list of the greatest items we make here.It may be more than 70 years old, but its impact and influence remains significant. Today it’s even helping revive the British wood industry decades after being ravaged by Dutch Elm Disease.On this week’s The Factory Next Door, Ercol’s Chairman and Creative Director, Henry Tadros, shows us around their purpose-built modern factory close to High Wycombe, the historic heartland of UK furniture-making.We question what makes a design timeless, watch the beauty and drama of wood bending, and learn why some outsourcing has been an important part of the company’s survival.Say hello on Instagram @thefactorynextdoorAnd if you want to vote for the show at the British Podcast Awards, you can at this website:www.britishpodcastawards.com/votingThe Factory Next Door is supported by AVEVA, a leader in industrial intelligence. Sign up to their bi-weekly newsletter about manufacturing here:www.aveva.com/factory